Project Details

Ardgillan Demesne is a 200-acre public park centred around Ardgillan Castle, a large country-styled house, with walled gardens located in North County Dublin. The Castle and grounds are a protected structure and were purchased by Fingal County Council in 1982.

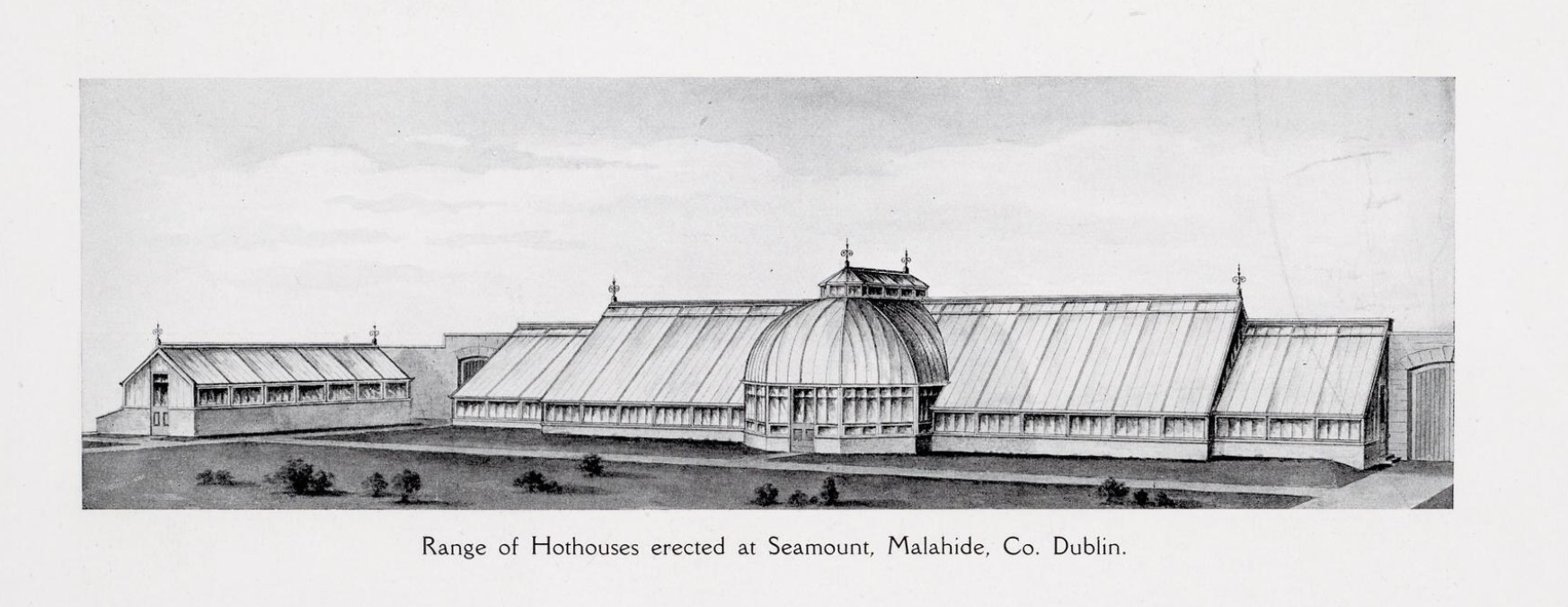

Oldstone Conservation was appointed as Main Contractor to construct 4 no. Glasshouses within the walled garden, two of the glasshouses are historic, “The Vinery” and “The Propagation House” dating from the 1880s and fabricated by MacKenzie & Moncur a leading company in the construction of hothouses (conservatories) at that time. The new glasshouses were completed and opened to the public at the official launch on 23rd May 2022.

Works

The four glasshouses consist of:

1. The Vinery

2. The Propagation House

3. The Fern House

4. The Orchid House

The Vinery

The Vinery is a MacKenzie Moncur glasshouse originally installed at Seamount, Malahide in the late 1800s. It was donated to Fingal Co Co, dismantled, transported and re-assembled in Ardgillan Demesne in the 1990s by the Ardgillan Operations team. It went into disrepair in 2012 and was subsequently dismantled in 2014 and placed in storage. As part of the design process a survey of the remaining glasshouse components was undertaken with component schedules and drawings prepared.

None of the original glazing survived and little remained of the original timber components however the Lantern, the metal elements (winder mechanisms & cast iron grilles) and 4no. doors were confirmed to be original to Seamount. The original timber components were pitch pine (no longer available) and hence Accoya was specified as a suitable alternative.

The initial task involved logging, tagging and transporting the Vinery components (timber & metal) to the Joiner’s workshop. Each component was cross checked with the tender schedule, missing elements were identified, sourced and/or reproduced. Shop drawings were prepared and submitted for approval prior to the manufacture of the timber elements.

Site works involved the temporary support of the existing metal truss, salvaging the historic cast iron floor grilles and slate water tanks for later re-use. The existing rising walls and foundations were removed and new footings installed. New structural steel windposts were installed to the footings at exact spacings to match the timber uprights of the glasshouse. Brick rising walls were then constructed enclosing the steel windposts. Reinforced concrete water tanks were installed (& received the original slate water tanks), and water pipes laid within the internal service trench for connection to the rainwater harvesting system.

Fabrication of the timber elements took place in the Joiners workshop. The Dome was complex in shape and the new curved structural members consisted of Glulam beams with the original steel sections affixed to the underside. Each timber upright within the glasshouse structure was connected to the rising wall and a steel windpost. The lantern was installed on top of the dome requiring the use of a small crane. The curved glazing required templates to be formed prior to manufacture.

Internally the original winder mechanisms were reinstated and made workable, the internal doors fitted, new terracotta tiles laid, the staging was installed with Valentia slate work tops and cast iron grilles fitted over the service trenches. A new electricity supply was completed and internal lights, heaters and sockets fitted. The water supply was connected and the rainwater harvesting system commissioned.

Propagation House

The Propagation House originally sat beside the Vinery at Seamount House. Unlike the Vinery however, it had never been re-assembled at Ardgillan. The approach taken was to retain and repair as much of the original fabric as possible. The original timber elements consist of Burmese Teak, as recommended at the time for humid environments, and the timbers that remained were in good condition. Any repairs to the timber were undertaken using Accoya. The metal components were generally intact and any replacement and/or replicas sourced from the UK.

Each of the stored elements (timber & metal) was tagged, logged and transported to the joiners’ workshop for cleaning, repair and re-assembling. Any missing timber components were reproduced to match the original details and any missing ironwork components ordered.

The Propagation House was positioned in a new green field location. Shop drawings were produced and approved and the site excavated to receive new foundations. Reinforced concrete water tanks were constructed within the floors of the Propagation House as part of the rainwater harvesting system. The rising walls were completed with steel windposts, the timber frame was brought from the workshop and assembled on site. The frame was supported and connected to the windposts in the rising walls. The internal winder mechanisms were restored and made operational. New staging was fitted with new Valentia slate tops. The glazing was inserted along with the lead flashings and downpipes. Cold frames were constructed on the southern side of the Propagation House. Electric and water supply was brought to the house with lights, sockets and heaters fitted. The external paths, stone walls and steps brought a finish to the works.

Fern & Orchid House

The existing glasshouse structures at these locations were demolished. Fabrication drawings for the new glasshouses were prepared and approved. New footings and drainage soakpits were formed, steel windposts were fitted and enclosed within the brick rising walls. The timber frame was manufactured in Accoya and spray painted in the joiner’s workshop before being erected on site. Each vertical member was aligned and connected to a steel windpost. Upon completion, the glazing, lead flashings and rainwater goods were fitted. A new electrical supply was brought to each glasshouse and fed to a distribution board. Electrical fittings consisted of actuators (window openers), tube heaters and lights. Water supply was made and taps installed.